China Plastic Injection Molding Companies | PTMS

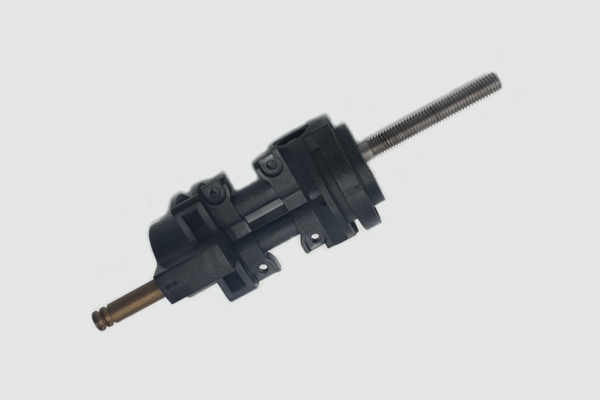

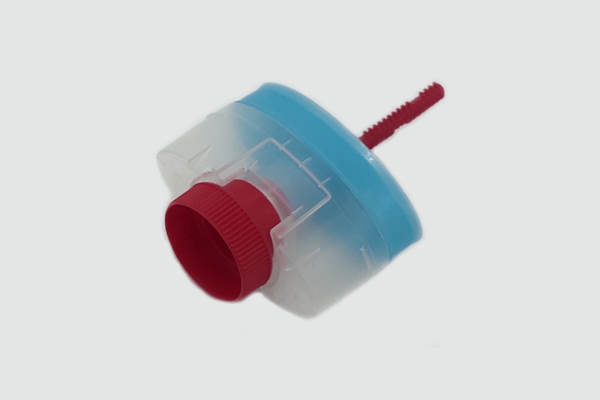

PTMS is a professional China plastic injection molding company and specialize in many different injection molding mass productions. Why we can provide such service to customers? Because our company have many advantages in such production. Enough Space. It has large areas for our shop, for example, 20000m2 workshop, 1000m2 warehouse, 1000m2 office. Skilled Employees. 150 operators, 15 engineers, 10 QC, 15 admin, so our team is very strong. All of the workers can make the job well, meanwhile, the QC can control the original plastic materials and make sure quality products. Injection Machines. 25 sets TOYO auto injection machines, it can save the production cost and make the production price lower. In the fact, we are not the best plastic injection molding companies in China, but our company has the ability to make OEM or ODM for the customers. We just make molds at the beginning, after many years’ efforts, we become a professional company, 70% of the products were exported to many diff